2021 Bacci BMT 4-axis CNC end profilng machine

or

Call (905)-451-8430

NEW Listing

Specifications

| Manufacturer | Bacci |

| Model | BMT |

| Year | 2021 |

| Stock Number | T4509RC |

| Voltage | 380V |

| Condition Rating | Very Good |

| Made in | Italy |

Description

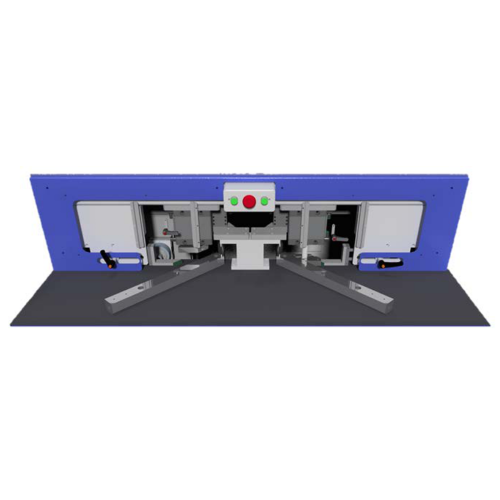

BACCI BMT 4-AXES CNC is the machining center for Mitre, Mortise, and Tenon of Stile and Rail Components

The Bacci BMT 4-Axis is Baccis’ new solution for producing mitred kitchen cabinet door components and is specifically configured for flexible, high volume production requirements. The Bacci BMT 4-Axis produces high-quality 45° mitred, mortised, and tenoned components for use in cabinet door construction.

Features

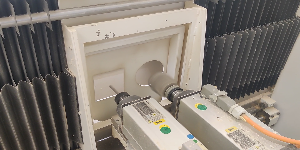

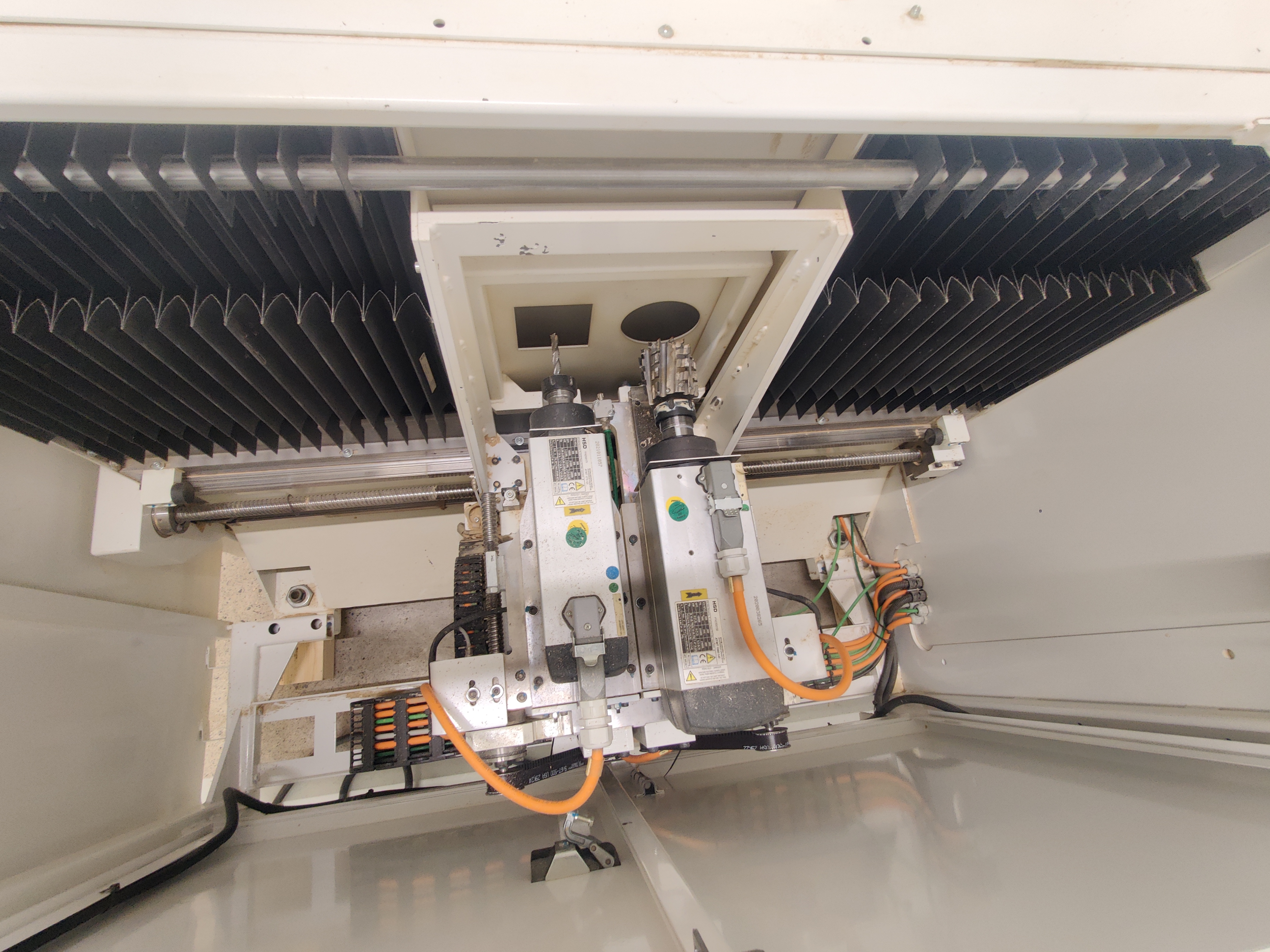

- Two (2) direct drive spindles, one for the mortise and one for the miter/tenon.

- Two (2) zone work tables for pendulum processing capability

- Opposing left and right reference fences for perfectly mitered corners.

- Side and top clamps for maximum clamping ability.

- Four (4) interpolated axes fully managed by the NC control.

- Longer (800mm) X-Axis stoke for machining even the widest parts.

- Automatic lubrication system for the 4-Axis NC controlled motion systems.

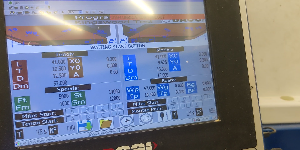

- Quick and flexible programming software for processing various profiles shapes and sizes.

- Easily recall previous programs manually or via bar code. The Bacci BMT 4-Axis CNC is the only machine to be equipped with a 4th NC controlled axis.

Benefits

- Complete elimination of any possible manual settings, other than for a tool change.

- More accurate positioning and faster cycle times. The common 3-Axes machine controls the Y-axis movement of the mortise and tenon spindles with pneumatic cylinders. Bacci, instead, uses independent NC-controlled drive motors for the mortise and tenon spindles. Thus the Y-Axis movement is faster and more accurate.

- A more reliable drive system over that of a pneumatic cylinder.